Electric vehicle (EV) batteries may last longer in the real world than manufacturing lab tests predict, according to a new study.

The researchers “surprisingly” found that charging and discharging based on driver data led to battery lifetimes 38% longer on average, compared to typical lab tests.

Their study is published in Nature Energy.

“We’ve not been testing EV batteries the right way,” says senior author Associate Professor Simona Onori, a researcher at Stanford University, USA.

“To our surprise, real driving with frequent acceleration, braking that charges the batteries a bit, stopping to pop into a store, and letting the batteries rest for hours at a time, helps batteries last longer than we had thought based on industry standard lab tests.”

Manufacturers can’t spend 10 years confirming that a new model will last for 10 years, so battery lifetime is normally tested by charging and discharging rapidly through hundreds or thousands of cycles.

It was thought that the rapid charge-discharge in lab tests would be better for battery performance compared to real world driving conditions, which includes lots of partial charging and discharging, and long periods where the car is parked.

This type of battery treatment is called “dynamic discharge.”

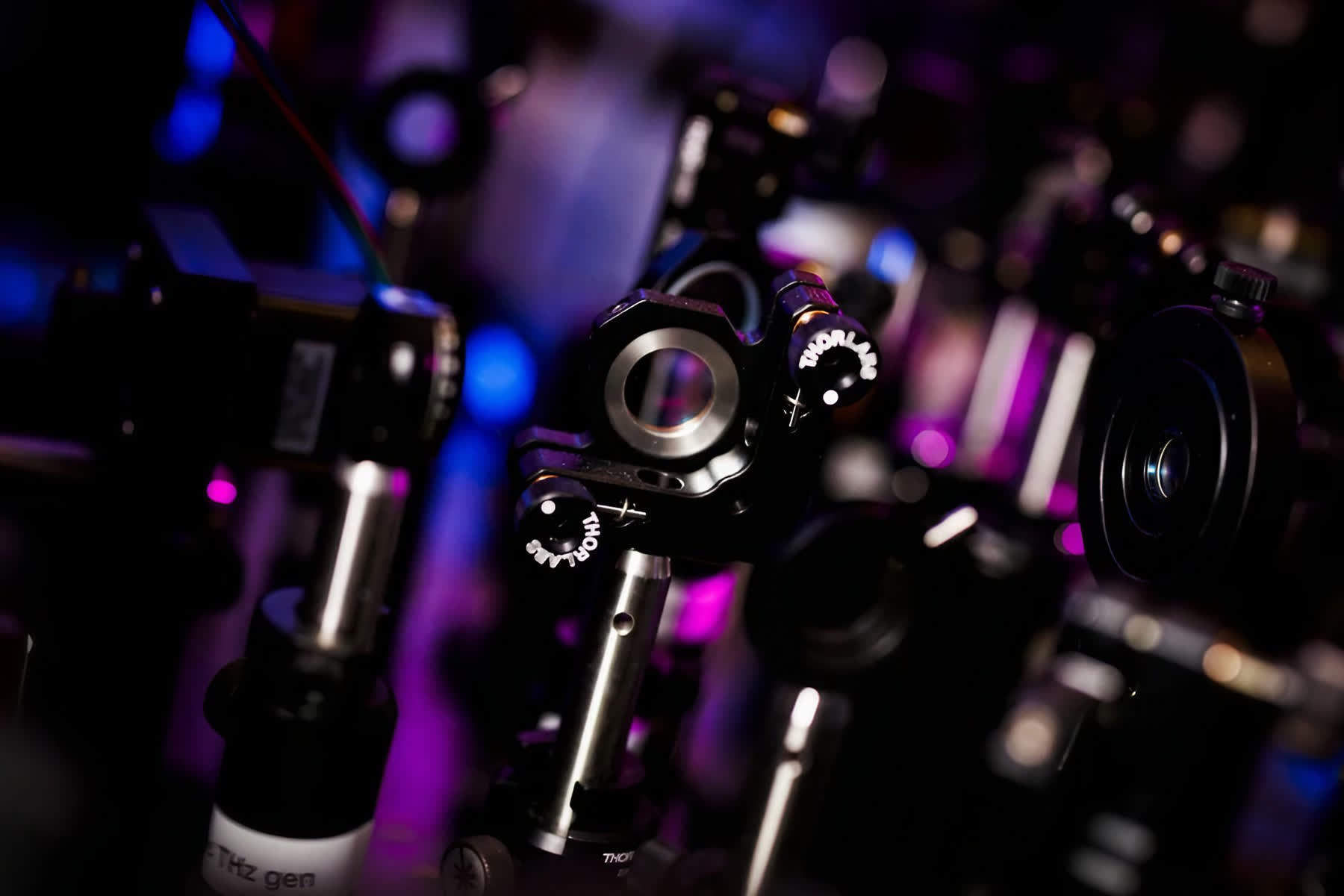

The researchers tested 92 commercial EV lithium-ion batteries over a 2-year period.

Some batteries were kept at a constant current, some were cycled neatly like they would be in a lab test, and some were treated with dynamic discharge cycles based on real-world driving data from 2 cities.

The real-world dynamic cycling also had variations depending on how cars were used – whether for long or short highway trips, urban driving, or a combination.

The team ran regular diagnostic cycles to see how far the batteries had degraded.

They found that the more dynamic a cycle, the longer the battery’s lifetime.

While they don’t know exactly why this is the case, a machine-learning algorithm they used suggested that tiny pulses of charge and discharge, coming from rapid accelerations and braking, played a big role.

The team argues for changing the ways that EV batteries are tested.

“There is a need to systematically adopt realistic cycling protocols when developing new battery materials and cell designs, not only in terms of optimisation but also in terms of mechanistic understanding,” they write in their paper.

“Going forward, evaluating new battery chemistries and designs with realistic demand profiles will be really important,” says co-author Dr Le Xu, a postdoctoral scholar at Stanford.

Leave a Comment