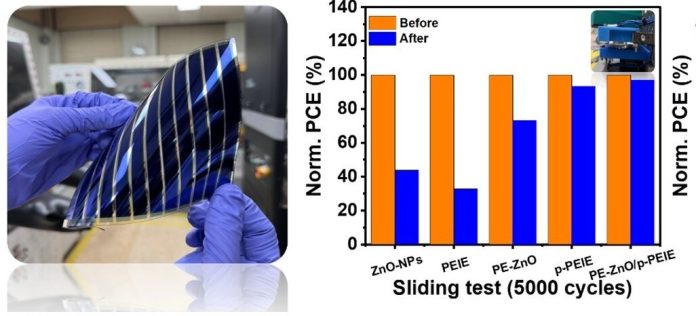

A research team has created a breakthrough thin-film material that makes electronic devices tougher and more durable.

This innovative material, which combines organic and inorganic layers, can be used in flexible solar cells, sensors, and other devices.

It stands out for its ability to handle physical stress, such as rolling and unrolling, without breaking or becoming damaged.

The study was published in the Chemical Engineering Journal.

Thin-film materials are widely used in modern electronics, but they often face problems during manufacturing or everyday use.

In roll-to-roll production—a common method for making flexible devices—delicate materials can develop defects.

Similarly, devices that need to bend, roll, or fold may experience damage over time.

One of the biggest challenges is delamination, where layers within the material separate, causing performance issues.

To solve this problem, the researchers developed a unique dual-layer thin-film material.

It combines flexible organic materials with strong inorganic materials, resulting in a material that is both tough and adaptable.

This dual-coating approach not only makes the material more durable but also protects it from chemical stress in harsh environments.

The new thin film is especially effective when used as an interfacial layer—where transparent electrodes meet active layers—in devices like solar cells and electronic displays.

It strengthens the bond between these layers, preventing damage while improving the overall performance and lifespan of the devices.

Dr. Dong-Chan Lim, the lead researcher, emphasized the wide-reaching impact of this technology.

“This innovation improves production efficiency for flexible devices and opens up new possibilities in industries like energy, robotics, and displays,” he said. “By boosting durability and reliability, it could make flexible devices more practical and accessible.”

One of the key benefits of this material is its potential to improve roll-to-roll manufacturing, which is critical for making flexible electronics at scale.

By reducing defects during production, the new material can increase yields and lower costs. This could help industries develop more advanced technologies while also strengthening local supply chains by reducing reliance on imported materials.

With applications in flexible solar panels, rollable displays, and wearable sensors, this thin-film material could shape the future of durable and lightweight devices.

By solving long-standing issues with flexibility and durability, it paves the way for more reliable electronics in a variety of cutting-edge fields.

Source: KSR.

Leave a Comment