A team of researchers has made a major breakthrough in battery technology, creating a lithium–sulfur battery that can fully charge in just 12 minutes and retain 82% of its capacity even after 1,000 charging cycles.

This advancement could pave the way for faster, more efficient batteries for electric vehicles and other eco-friendly technologies.

Lithium–ion batteries are widely used today but have some limitations, such as lower energy storage and higher costs.

Lithium–sulfur batteries, on the other hand, have gained interest because sulfur is cheap and these batteries can store more energy.

However, existing lithium–sulfur batteries have struggled with slow charging speeds, reduced battery capacity during rapid charging, and performance issues caused by sulfur compounds that form during use.

To solve these problems, Professor Jong-sung Yu and his team at DGIST developed a new material made from nitrogen-doped porous carbon.

This innovative material improves how sulfur interacts with the battery’s other components, allowing for much faster charging without losing capacity.

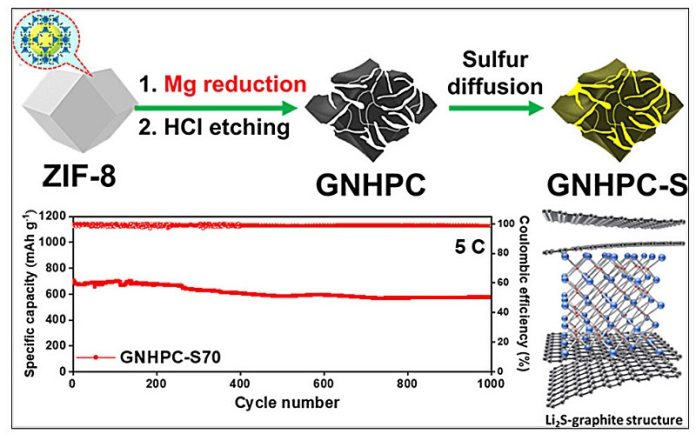

The team created the material using a method called magnesium-assisted thermal reduction. They combined magnesium with a substance called ZIF-8, a metal-organic framework.

At high temperatures, the magnesium reacted with nitrogen in the ZIF-8, creating a strong, stable carbon structure filled with tiny pores.

These pores increased the amount of sulfur the battery could hold while improving its connection to the liquid electrolyte, which carries charge inside the battery.

When the team tested their new material in a lithium–sulfur battery, it delivered outstanding results. The battery charged fully in just 12 minutes and reached a high capacity of 705 milliampere-hours per gram (mAh/g), which is 1.6 times better than conventional lithium–sulfur batteries.

The battery also showed impressive durability, retaining 82% of its capacity after 1,000 charge–discharge cycles.

This stability is thanks to the nitrogen-doped carbon surface, which prevents sulfur compounds from moving around and damaging the battery’s performance.

Collaborating with Argonne National Laboratory, the researchers also used advanced imaging techniques to study the material closely. They found that lithium sulfide formed in specific patterns within the carbon layers, proving that the material’s design improved the battery’s charging speed and energy storage.

“This study shows how a simple method using magnesium can dramatically improve lithium–sulfur batteries,” said Professor Yu. “We hope this work will bring us closer to commercializing this promising battery technology.”

With this breakthrough, the future of fast-charging, long-lasting batteries looks brighter than ever, potentially transforming electric vehicles and other renewable energy technologies.

Source: KSR.

Leave a Comment